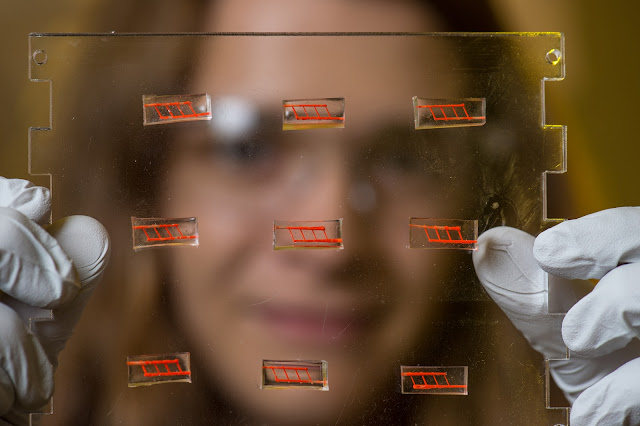

Samantha Paulsen,

a bioengineering graduate student in Jordan Miller’s lab at Rice University,

holds a plate on

which several of 3-D-printed silicone constructs have been mounted.

The constructs,

which are each about the size of a small candy gummy bear, have been

injected with red

dye to better show the network of small vessels inside. (Photo by Jeff Fitlow)

(November 3, 2015) Rice, Penn researchers create implant

with network of blood vessels

Using sugar, silicone and a 3-D printer, a team of

bioengineers at Rice University and surgeons at the University of Pennsylvania

have created an implant with an intricate network of blood vessels that points

toward a future of growing replacement tissues and organs for transplantation.

The research may provide a method to overcome one of the

biggest challenges in regenerative medicine: How to deliver oxygen and

nutrients to all cells in an artificial organ or tissue implant that takes days

or weeks to grow in the lab prior to surgery.

Using an

open-source 3-D printer that lays down individual filaments of sugar glass one

layer at a time,

the researchers “printed” a lattice of would-be blood vessels.

(Credit: Rice University)

The new study was performed by a research team led by Jordan

Miller, assistant professor of bioengineering at Rice, and Pavan Atluri,

assistant professor of surgery at Penn. The study showed that blood flowed

normally through test constructs that were surgically connected to native blood

vessels. The report was published in the journal Tissue Engineering Part C:

Methods.

Researchers at

Rice University and the University of Pennsylvania demonstrated that blood

flowed normally

through the network of small channels in the silicone construct,

which is about the

size of a small candy gummy bear. (Credit: Jordan S. Miller/Rice University)

Miller said one of the hurdles of engineering large

artificial tissues, such as livers or kidneys, is keeping the cells inside them

alive. Tissue engineers have typically relied on the body’s own ability to grow

blood vessels — for example, by implanting engineered tissue scaffolds inside

the body and waiting for blood vessels from nearby tissues to spread to the

engineered constructs. Miller said that process can take weeks, and cells deep

inside the constructs often starve or die from lack of oxygen before they’re

reached by the slow-approaching blood vessels.

From left, Jordan

Miller, Samantha Paulsen and Anderson Ta

stand with the 3-D printer they used

to create the silicone constructs.

(Credit: Jeff Fitlow/Rice University)

“We had a theory that maybe we shouldn’t be waiting,” Miller

said. “We wondered if there were a way to implant a 3-D printed construct where

we could connect host arteries directly to the construct and get perfusion

immediately. In this study, we are taking the first step toward applying an

analogy from transplant surgery to 3-D printed constructs we make in the lab.”